-

Products

New Items

- Locators with bore hole, for spring plungers

- Locators smooth, for spring plungers

- Holders for spring plungers

- Index Plungers Mini Indexes with mounting flange

- Index Plungers with locking mechanism push-lock

- Index Bolts threadless, weldable

- Spring Push Plungers with mounting flange, horizontal

- Flat Knurled Nuts DIN 467

- High Knurled Thumb Screws DIN 464

- Rubber Metal Buffers waisted

- Hinges

- Hinges

- Hinges elongated on one side

- Hinges elongated on both sides

- Hinges long version

Further Information:Product Groups- Forestry Tools

- Accessories

- Promotional Boxes

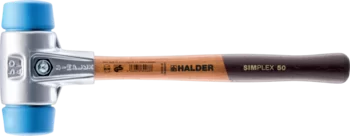

- SIMPLEX soft-face mallets, cast iron housing

- SIMPLEX soft-face mallets, reinforced cast iron housing

- SIMPLEX soft-face mallets, aluminium housing

- SIMPLEX soft-face mallets, cast iron housing, with "Stand-Up"

- SIMPLEX soft-face mallets, cast iron housing, 50:40

- SIMPLEX soft-face mallets, aluminium housing, 50:40

- SIMPLEX soft-face mallets, cast iron housing, extra short handle

- SIMPLEX soft-face mallets, cast iron housing, with "Stand-Up", extra short handle

- BASEPLEX soft-face mallets

- SIMPLEX sledge hammers, cast iron housing

- SIMPLEX sledge hammers, reinforced cast iron housing

- SIMPLEX sledge hammers, cast iron housing, with "Stand-Up"

- SUPERCRAFT soft-face mallets

- BLACKCRAFT soft-face mallet

- SECURAL soft-face mallet

- SUPERCRAFT sledge hammers

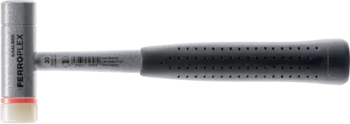

- FERROPLEX Combi Hammer

New Items- SIMPLEX soft-face mallets, 50:40 TPE-soft / TPE-mid; with cast iron housing and high-quality wooden handle

- SIMPLEX soft-face mallets, 50:40 TPE-soft / TPE-mid; with aluminium housing and high-quality wooden handle

- SIMPLEX insert, 50:40 TPE-mid, grey

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D60, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D80, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Promotional Box Automotive SIMPLEX soft-face mallet D40, copper / soft metal plus puncher

- BLACKCRAFT Promotional Box Automotive BLACKCRAFT soft-face mallet D60 plus Magnetic Holder

- Promotional Box Dreamteam Door and Window Construction SIMPLEX soft-face mallet 50:40, TPE-soft / TPE-mid and SECURAL plus soft-face mallet

- Service

- Newsroom

- Company

- Contact

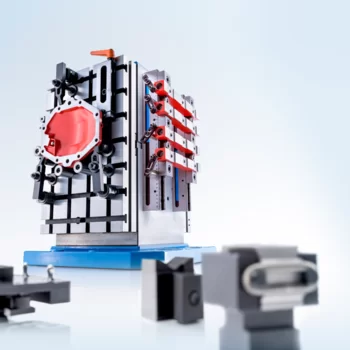

Multi-Vices MS 125eco

EH 1700.

The all-round clamping system is a classic for conventional clamping and gripp clamping. It is suitable for all common milling. Clamping of unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece.

The MS 125eco is designed for fast machining of unmachined/semi-finished parts as well as of finished products. It is equally suitable for gripp clamping in the first clamping as well as for conventional clamping in the second clamping without refitting.

- Ground jaws for high precision in the machining of workpieces

- High-pressure spindle with mechanical power intensifier (operation with torque wrench)

- Up to 40 kN clamping force (linearly increasing, at max. 30 Nm)

- Solid base made of GGG 60, top and bottom surface ground

- Threats M8 on both sides for workpiece stop

- Precise alignment slots in the ground bottom surface for an optimal alignment on the machine table

Scope of supply:

- 1 piece MS 125eco

- 1 set step jaws for gripper studs

- 4 pieces gripper studs, pointed

- 4 pieces clamping claws

- 3 pieces wrenches

All components of the product ranges "conventional clamping" and "gripp clamping" as well as the accessories for the Multi-Vice MS 125 are fully compatible to MS 125eco. For horizontal machining Halder basic elements (angles/cubes) can be used.

Your selection resulted in 1 hits

More details

Material

- Ductile cast iron (GGG 60)

Notes

This is a discontinued article.

Further products

RoHS compliant

Compliant according to Directive 2011/65/EU and Directive 2015/863.

Does not contain SVHC substances

No SVHC substances with more than 0.1% w/w contained - SVHC list [REACH] as of 27.06.2024.

Does not contain Proposition 65 substances

No Proposition 65 substances included.

https://www.P65Warnings.ca.gov/

Free from Conflict Minerals

This product does not contain any substances designated as "conflict minerals" such as tantalum, tin, gold or tungsten from the Democratic Republic of Congo or adjacent countries.

What is the difference between the MS 125 and an ordinary machine vice?

Since it comes with a modular design and can be paired with a large variety of jaws and associated equipment, the MS 125 is considerably more versatile than a standard machine vice.

Contact Form

Information Material

Information material Standard Parts Information material Workholding Systems Information material Aviation ProductsNews

Have a look to our current new parts:

Threaded Lifting Pins with handle Bedding Supports Spring Push Plungers Accessories for spring plungers Index Plungers / Index Bolts Damping Elements Hinges Knurled Nuts / Knurled Thumb Screws