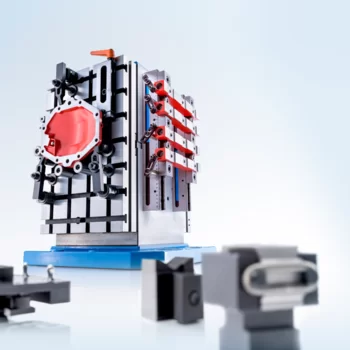

Centering Clamping Mandrels

EH 23340.

The centering clamping mandrels are often used in mechanical engineering. However, thanks to their simple operation and quick assembly, they can be used in all industries.

Centering clamping mandrels are used for centering and clamping of workpieces with a locating hole.

The centering clamping mandrels have the following characteristics:

- Very high accuracy for turning/milling processes

- Ideal for secondary operations on turned parts

- Hardened and coated screw for long service life

- Clamping body can be machined very easily (for adaptation to bore diameter)

Your selection resulted in 7 hits

More details

- d1 min.: 8 mm

- d1 max.: 12.4 mm

- d2 -0.05: 29.72 mm

- d3: M3

- d4: 21 mm

- d5: M4

- h1: 15 mm

- h2: 16 mm

- h3: 21.8 mm

- l1: ~ 6 mm

- l2: 8 mm

- Number of segments: 4

- WS WS1: 3 mm

- WS WS2: 2 mm

- Clamping force max.: 3 kN

- Tightening torque max.: 3.5 Nm

- Location hole H7: 29.72 mm

- Weight: 58 g

- d1 min.: 12.2 mm

- d1 max.: 14.2 mm

- d2 -0.05: 31.5 mm

- d3: M3

- d4: 23.1 mm

- d5: M6

- h1: 15 mm

- h2: 19 mm

- h3: 24.9 mm

- l1: ~ 6 mm

- l2: 12 mm

- Number of segments: 4

- WS WS1: 5 mm

- WS WS2: 2 mm

- Clamping force max.: 6 kN

- Tightening torque max.: 12 Nm

- Location hole H7: 31.5 mm

- Weight: 62 g

- d1 min.: 13.5 mm

- d1 max.: 20 mm

- d2 -0.05: 37.5 mm

- d3: M3

- d4: 29 mm

- d5: M8

- h1: 15 mm

- h2: 19 mm

- h3: 24.9 mm

- l1: ~ 6 mm

- l2: 14 mm

- Number of segments: 6

- WS WS1: 6 mm

- WS WS2: 2 mm

- Clamping force max.: 8 kN

- Tightening torque max.: 24 Nm

- Location hole H7: 37.5 mm

- Weight: 99 g

- d1 min.: 18 mm

- d1 max.: 27 mm

- d2 -0.05: 50 mm

- d3: M4

- d4: 39.4 mm

- d5: M10

- h1: 17.5 mm

- h2: 22.2 mm

- h3: 28.6 mm

- l1: ~ 7 mm

- l2: 17 mm

- Number of segments: 6

- WS WS1: 8 mm

- WS WS2: 2.5 mm

- Clamping force max.: 13 kN

- Tightening torque max.: 42 Nm

- Location hole H7: 50 mm

- Weight: 191 g

- d1 min.: 25.4 mm

- d1 max.: 35.3 mm

- d2 -0.05: 56 mm

- d3: M4

- d4: 45.5 mm

- d5: M12

- h1: 20.6 mm

- h2: 25.4 mm

- h3: 31.8 mm

- l1: ~ 7 mm

- l2: 21 mm

- Number of segments: 6

- WS WS1: 10 mm

- WS WS2: 2.5 mm

- Clamping force max.: 15 kN

- Tightening torque max.: 105 Nm

- Location hole H7: 56 mm

- Weight: 306 g

- d1 min.: 30 mm

- d1 max.: 51 mm

- d2 -0.05: 75.5 mm

- d3: M5

- d4: 63.9 mm

- d5: M16

- h1: 27 mm

- h2: 31.8 mm

- h3: 39.6 mm

- l1: ~ 12 mm

- l2: 20 mm

- Number of segments: 6

- WS WS1: 14 mm

- WS WS2: 3 mm

- Clamping force max.: 26 kN

- Tightening torque max.: 200 Nm

- Location hole H7: 75.5 mm

- Weight: 762 g

- d1 min.: 30 mm

- d1 max.: 77 mm

- d2 -0.05: 107.5 mm

- d3: M6

- d4: 92.5 mm

- d5: M16

- h1: 32.3 mm

- h2: 37.6 mm

- h3: 45.5 mm

- l1: ~ 12 mm

- l2: 20 mm

- Number of segments: 8

- WS WS1: 14 mm

- WS WS2: 4 mm

- Clamping force max.: 26 kN

- Tightening torque max.: 200 Nm

- Location hole H7: 107.5 mm

- Weight: 1832 g

Material

Body

- Steel, blackened

Clamping screw

- Case-hardened steel, case-hardened

Notes

Customized design on request.

Assembly

The centering clamping mandrel can be machined to the required seating diameter (e.g. by turning/milling). It must be noticed that before machining the centering clamping mandrel, it will be expanded approx. 0.1 mm over the clamping diameter. To machine the mandrel, a nut will be provided.

Further or detailed information can be found in the assembly and operating instructions.

Further products

RoHS compliant

Compliant according to Directive 2011/65/EU and Directive 2015/863.

Does not contain SVHC substances

No SVHC substances with more than 0.1% w/w contained - SVHC list [REACH] as of 27.06.2024.

Does not contain Proposition 65 substances

No Proposition 65 substances included.

https://www.P65Warnings.ca.gov/

Free from Conflict Minerals

This product does not contain any substances designated as "conflict minerals" such as tantalum, tin, gold or tungsten from the Democratic Republic of Congo or adjacent countries.